Task 6.2: Read-out technology: design and optimization for fibre sensors

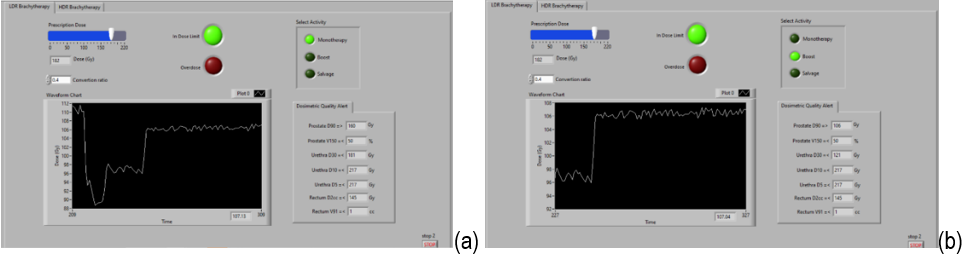

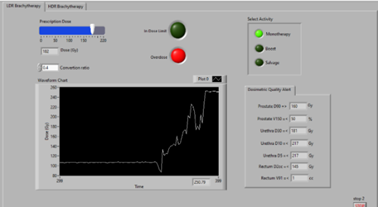

Examples of the readout software produced for the clinical trials are presented for interest. Fig. 6.2.1 shows the developed user interface, where real-time signal of absorbed dose (Gy) is graphically displayed for user application (bottom left waveform chart). Output signal of the sensor measured in counts/ frequency are converted into radiation activity or received radioactive dose through the calibration process prior in-vivo measurements. The control tab above the chart allows the change of conversion ratio based on different sensor prototype used during the measurement. The engage buttons on the top right corner denote the types of LDR brachytherapy modality either delivered on its own (Monotherapy), combined with External Beam Radiotherapy (Boost) or in the treatment of locally recurrent prostate cancer (Salvage). Right bottom tab of the figure indicates the dose-volume histogram measurement constraints for LDR-BT for prostate for each selected treatment protocols (monotherapy, boost or salvage). The dose-volume histogram constraints value of each treatment modality for LDR-BT for prostate are indicated in the system.

The clinician has the options to manually alter the limit constraint on the top left pointer slide (in blue), either based on the reference value displayed on the dosimetric quality alert tab or depending on the limitation of prescription dose/isodose levels indicated from the treatment planning system. The limitation dose varied depends on the sensor/target location (prostate, urethra or rectum) and treatment protocols (monotherapy, boost or salvage). Apart from real-time radiation dose chart display, colour indicator is used to visualise the dose conformity to the treatment plan. Two red and green LED indicators above the real-time chart enable the toggles between two different states based on the selected prescription dose. The red LED indicates constraint has been exceeded by (overdose) while the green LED indicates the dose measured is still within the amount of planned dose. This allows the visual error alert system for the user to easily response when overdose measurement takes place. Fig. 6.2.2 illustrates the red alert indicator toggled on, notifying the user that the dose exceeds the limit during seed implantation.

Task 6.3: Performance testing

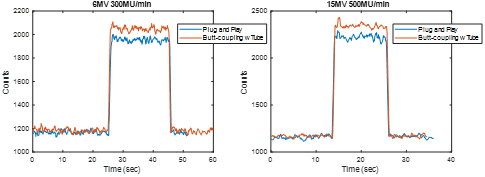

Fibres were exposed to different X-ray pulse energies, namely 6 MV and 15 MV from a Siemens Oncor Avant Garde linear accelerator in a clinical setting. For each energy, high dose rate (HDR) pulses of 300MU/min for 6MV and 500MU/min for 15MV were used, whereas low dose rate (LDR) pulses of 50MU/min for both energies were also investigated. All radiation were performed with a radiation dose of 100 Monitor unit (MU), where 1MU approximately equal to 1cGy. All measurements were taken in the Galway clinic, Ireland.

Fig. 6.3.2 illustrates the results of the photon counts comparing two different sensor designs, namely Plug and Play (PnP) in blue and simple butt-coupling sensor in tube (tube) in red. The rectangular plateau at each graph represents the signal (counts) detected when the radiation beam was on. The length of the radiation beam on is dependent on the dose rate and radiation dose delivered. The average dark count rate (DCR), i.e. the background noise when there is zero light input for the measurement at 0.5pe threshold, was calculated to be 1158.6 counts during the PnP measurement and 1177.9 for the sensor in tube.

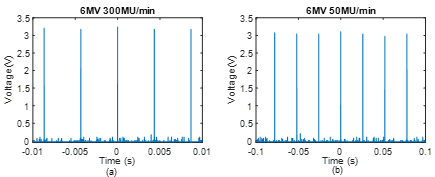

The analogue output pulses were captured using an oscilloscope during irradiation and the pulse repetition rate over a selected time range captured was observed for comparison. Fig. 6.3.3 illustrates the analogue pulses captured using an oscilloscope during irradiation on PnP sensor. The timescale was set to capture a range of multi-pulses for calculation of pulse repetition rate during irradiation at different energy and dose rates. A higher pulse frequency was observed for the high dose rate (Fig. 6.3.3(a)), with a relatively lower pulse frequency for the case of LDR radiation (Fig. 6.3.3(b)).

Analogue Output from Oscilloscope

Brachytherapy

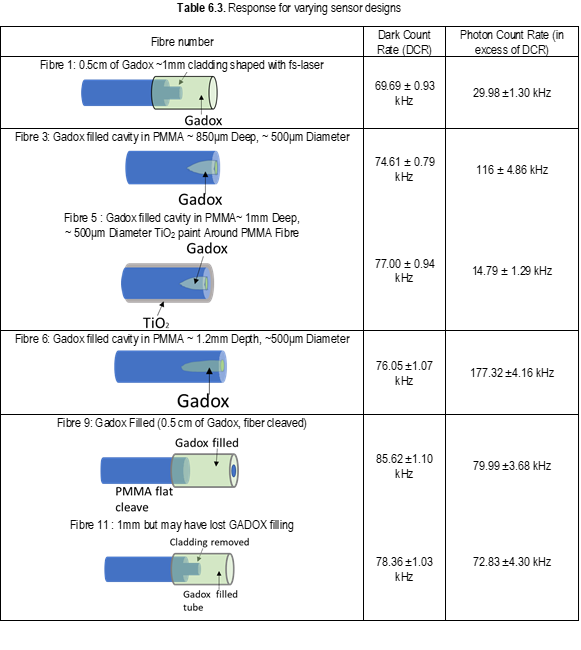

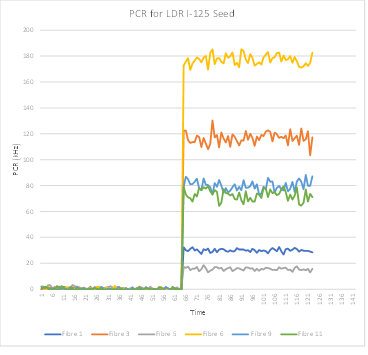

Table 6.3 shows the different fibre sensor designs using GADOX and the corresponding dark count rate and photon count rate and are further compared in Fig. 6.3.5. In all cases the dosimetry system could record a photon count rate well in excess of the dark count rate. The fsL machined cavity sensor with a depth of 1.2mm recorded the highest sensitivity, while the cavity with the TiO2 coating recorded the lowest signal. This is due to the radiation attenuation associated with Ti.